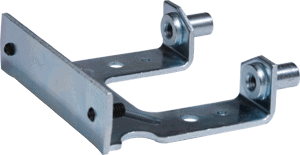

Progressive Die Stamping of a Mounting Bracket for a Security System

The project highlighted here exemplifies our ability to provide progressive die stamping as well as a number of ancillary processes. This flexibility, in-depth process, and industry knowledge makes Manor Tool & Manufacturing Company a single source solution for progressive die stamped components and assemblies.

Designed for use as a rear mounting assembly bracket for an automatic door security system, this component is composed of .120″, ¼ hard cold rolled steel and C1022 steel. Stamped on our 150-ton progressive die press, it features dimensions of 3.3″ in length, 4.2″ in width, and 1.3″ in height, and is manufactured to tolerances of ±0.002″.

The stamped part and threaded sleeves are tapped, the sleeves are then spot welded into place. The completed component is then zinc plated, followed by the insertion of set screws.

At Manor, we take quality seriously. Throughout the manufacturing and assembly process this product is subject to stringent quality measures such as visual and dimensional inspections. Thanks to the work of our fabrication, assembly, and certified welding team, the client awarded us the job of manufacturing all 40 components for the entire assembly, and has since placed multiple re-orders.

To learn more about this project, or the processes used to manufacture it, see the table below or contact us directly.

Highlights of this Progressive Die Stamping Project

| Progressive Die StampingCapabilities Applied/Processes: |

|

|---|---|

| Equipment Used to Manufacture Part: |

|

| Overall Part Dimensions: |

|

| Overall Part Dimensions: |

|

| Material Used: |

|

| In process testing/inspection performed: |

|

| Industry for Use: |

|

| Volume: |

|

| Delivery/Turnaround Time: |

|

| Delivery Location: |

|

| Standards Met: |

|

| Product Name: |

|