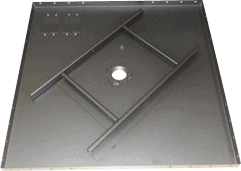

Custom Fabrication of Steel Flat Screen Wall Mounting Assembly

To manufacture this ceiling tray assembly, cold rolled steel and CQ were cut using hard tooling. In order to ensure adhesion, heat was properly applied during spot-welding.

Simultaneously, welds were monitored for aesthetic appeal, smoothness, and proper depth. The tightest tolerance held during this process was +/- .0025. The material measured .075 inches in thickness, 26 inches in length, 26 inches in width, and 1.13 inches tall. The custom fabrication project took three to four weeks to complete, and is appropriate for flat screen wall mounting.

To learn more about this project, or the processes used to manufacture it, see the table below or contact us directly.

Highlights of this Custom Fabrication Project

| Product Name: |

|

|---|---|

| Capabilities Applied/Processes: |

|

| Tightest Tolerances: |

|

| Material Thickness: |

|

| Product Length: |

|

| Product Width: |

|

| Product Height: |

|

| Product Weight: |

|

| Cutting Method: |

|

| Base Material: |

|

| Packaging: |

|

| Special Feature: |

|

| Secondary Operations Applied: |

|

| Industry for Use: |

|

| Delivery Time: |

|

| Drawing Type Accepted: |

|